Scantech Professional 3D Scanners and 3D System

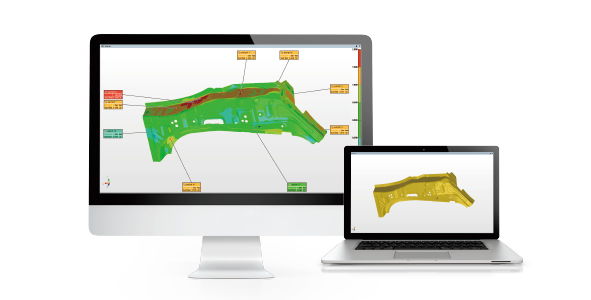

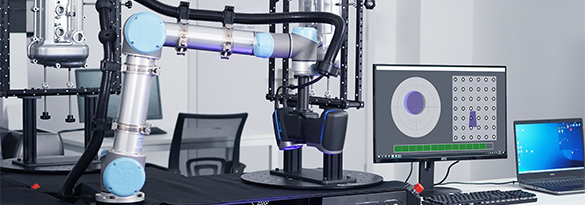

Scantech 3D scanners are non-contact metrology systems that utilize laser or structured light-based scanning technology. Optical 3D scanners are the optimal 3D metrology solutions to drive your business to great success because of their portability, efficiency and high precision. Scantech supplies professional handheld 3D scanner and automated 3D inspection system in all product manufacturing and production phases.

These innovative professional 3D laser scanners increase your productivity and optimize your product life cycle management without the need to compromise between accuracy and efficiency.

Due to the ability of our 3D scanner to measure tough-to-reach and complex geometrical features with precision and reliability, Scantech 3D scanning technology has been widely adopted in various industries. Engineers, product designers, and researchers use 3D scanners for automotive, aerospace, heavy machinery and 3D printing.